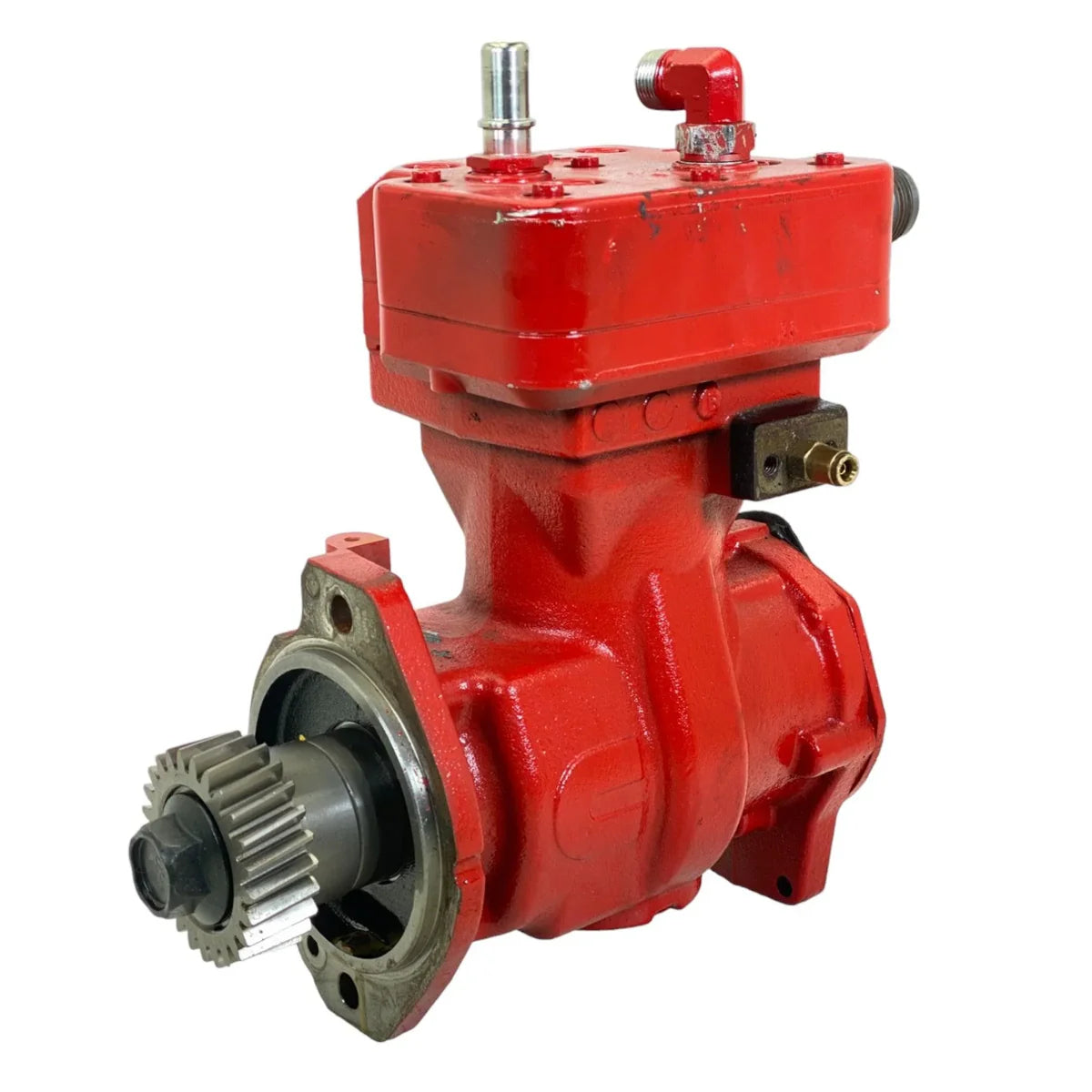

1650792047 | Genuine Cummins® Air Compressor Kit 12L ISX/QSX

1650792047 | Genuine Cummins® Air Compressor Kit 12L ISX/QSX is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

Need a quote?

Need a quote?

Contact us — we’ll send you a quick and accurate offer!

- help@forcetruckparts.com

- +1 (828) 233-5509

Return Within 30 Days

Return Within 30 Days

- The item can be returned within 30 days from the date of receipt.

- Not satisfied? Contact us by email or phone for return instructions or exchange

Shipping Terms

Shipping Terms

- Enjoy free shipping on orders over $100.

- Orders placed before 6:30 PM (EST) are shipped the same day.

Description:

An air compressor 1650792047 is a machine that converts power (from an electric motor, diesel, or gasoline engine) into pressurized air by drawing in air from the atmosphere and compressing it to a higher pressure. That compressed air can then be used to power tools, inflate tires, run machinery, or even support braking systems (like in trucks).

Part Number: 1650792047

Condition: New

Manufacture/Brand: Cummins

Fits 1650792047 For Cummins EPA13 12 liter ISX/QSX

Engines ISX12 CM2350 X102, ISX12 G CM2180 EJ, ISX12/ISX11.9 CM2250, ISX12N CM2380 X120B, QSX11.9 CM2250 ECF

Purpose of using 1650792047:

1. Powering Pneumatic Tools

2. Inflating Tires and Equipment

3. Spray Painting & Coating

4. Industrial and Manufacturing Applications

5. Air Braking Systems (Vehicles & Trains)

6. HVAC and Refrigeration Systems

7. Cleaning & Drying

8. Energy Storage & Pneumatic Control

|

Signs of a Bad Air Compressor Kit 1650792047:

|

1. Low Air Pressure or Weak Output Symptoms:

Possible Causes:

2. Unusual Noises Symptoms:

Possible Causes:

3. Overheating Symptoms:

Possible Causes:

4. Excess Moisture or Oil in the Air Lines Symptoms:

Possible Causes:

5. Electrical Problems Symptoms:

Possible Causes:

6. Air Leaks or Hissing Sounds Symptoms:

Possible Causes:

7. Vibration or Shaking Symptoms:

Possible Causes:

8. Tank or Pressure Gauge Problems Symptoms:

Possible Causes:

9. Excessive Oil Consumption (Oil-Lubricated Types) Symptoms:

Possible Causes:

10. Complete Failure to Start Symptoms:

Possible Causes:

|

About the Manufacturer – Cummins:

Cummins is a leading American manufacturer of diesel and natural gas engines, as well as power generation systems and emissions solutions. Founded in 1919 and headquartered in Columbus, Indiana, Cummins is known globally for its durable, high-performance engines used in trucks, buses, construction equipment, agriculture, and power systems.

The brand is widely respected for its innovation in clean diesel technology, including aftertreatment systems, turbochargers, and advanced electronics that help reduce emissions while maximizing engine efficiency and reliability.